IG-541

Non-toxic fire protection of valuables and buildings – without consequential damage from water and chemicals with IG-541 fire protection.

Overview.

Non-toxic fire protection of valuables and buildings – without consequential damage from water and chemicals with IG-541 fire protection

In the event of a fire, when IG-541 is discharged, it mixes with the air present in the room to create a mixture that comprises of 67.3% Nitrogen, 12.5% Oxygen, 17% Argon and 3.2% Carbon Dioxide.

This discharge mixture makes IG-541 singularly unique. No other inert gas has the unique ability to rapidly extinguish a fire yet at the same time provide a safe environment for any person within the occupied area by decreasing cardiac distress and maintaining arterial blood oxygenation and mental performance in low oxygen levels.

Trade Names.

Inergen, Inertech IG541, I-Flow IG541, Proinert IG541

Chemical Composition.

IG‑541 is a colourless, odourless, electrically non‑conductive gas with a density approximately the same as that of air. It is an inert gas mixture consisting nominally of 52% Nitrogen, 40% Argon and 8% CO2.

Gas Specification.

The gas specification is usually confirmed with a certificate of conformity (COC) from the manufacturer. It’s also important to ensure each specification is maintained during the 10-year testing and a new COC is provided confirming each requirement below by your supplier for the new re-filled or re-tested agent.

The mixture specification for IG-541 is as follows:

a) carbon dioxide percentage range 7.6% to 8.4%.

b) argon percentage range 37.2% to 42.8%.

c) nitrogen percentage range 48.8% to 55.2%.

Extinguishant IG-541 shall comply with the specification shown below:

| Component | Argon | Nitrogen | Carbon Dioxide |

|---|---|---|---|

| Purity | 99.997% by volume, min. | 99.99% by volume, min. | 99.5% by volume, min. |

| Moisture | 4 ppm by mass, max. | 5 ppm by mass, max. | 10 ppm by mass, max. |

| Oxygen | 3 × 10−6 by mass, max. | 3 × 10−6 by mass, max. | 10 × 10−6 by mass, max. |

Physical Properties.

| Property | Units | Value |

|---|---|---|

| Molecular mass | n/a | 34.00 |

| Boiling point at 1,013 bar (absolute) | °C | - |

| Freezing point | °C | - |

| Critical temperature | °C | - |

| Critical pressure | bar | - |

| Critical volume | cm3/mol | - |

| Critical density | kg/m3 | - |

| Vapour pressure 20 °C | bar abs | - |

| Liquid density 20 °C | g/ml | - |

| Saturated vapour density 20 °C | kg/m3 | - |

| Specific volume of superheated vapour at 1,013 bar and 20 °C | m3/kg | 0.706 |

Design Concentrations.

| Standard | Class A | Higher Hazard Class A / Class C | Class B |

|---|---|---|---|

| (BS) EN 15004 | 39.9% | 45.7% | 48.1% |

| NFPA 2001 | 34.2% | 38.5% | 40.3% (n-heptane) |

| APSAD | 39.9% | 41.0% | Subject to hazard |

| ISO 14520 | 39.9% | 39.9% | 43.9% |

| LPCB | 39.1% | 42.1% | 44.6% |

| FM 5600 | 34.9% | 39.2% | 42.2% |

| UL 2127 | 36.5% | 41.0% | 42.2% |

Loael, Noael & Minimum Safety Precautions.

The below is based on the requirements of EN 15004 which is the most common design standard in the UK and other European areas.

| Property | Value |

|---|---|

| No observed adverse effect level (NOAEL) | 43.0% |

| Lowest observed adverse effect level (LOAEL) | 52.0% |

| Concentration | Time delay device* | Automatic / Manual Switch** | Lock-off device*** |

|---|---|---|---|

| Up to and including the NOAEL | Required | Not Required | Not Required |

| Above the NOAEL and up to the LOAEL | Required | Required | Not Required |

| LOAEL and above | Required | Required | Not Required |

* Time delays are usually integrated within the main gas extinguishing panel to allow a 30 second delay before the system discharges. Hold off buttons are also usually located adjacent the exits of the enclosure.

** Automatic / Manual switches are usually integrated into the main gas extinguishing panel located at the entrance of the protected area.

*** Lock-Off devices are usually manual isolation valves installed within the pipework and again located at the entrance of the protected area.

IG-541 Quantity Calculation.

Typically, gaseous extinguishing systems are used for protecting electronic equipment in data rooms or similar, we have therefore prepared a quick calculation to help understand and estimate the quantity IG-55 agent required in your enclosure. The factor provided below is also based on a design temperature of 20°C and an altitude of 0, changes in either will have a small effect on the agent quantity

Design Concentration = 45.7% (Higher Hazard Class A)

Flooding Factor = 0.8689

Volume of enclosure in M³ x Flooding Factor = Quantity required in KG

[Example assuming room volume of 150m³]

150 x 0.8689 = 130.335kg

For a calculation spreadsheet in excel format or for quantity calculations outside of these parameters, please contact us directly at

hello@mepfire.com.

Typical Cylinder Fill Weights, Sizes, Pressures & Quantity Calculator.

Inert gas cylinders come in a range of sizes however the below is reflective of the most common sizes and pressures and corresponding fill weights for reference.

| Pressure | 67 Litres | 80 Litres | 140 Litres |

|---|---|---|---|

| 200 bar | 20.17kg | 24.1kg | 42.1kg |

| 300 bar | - | 33.5kg | 58.5kg |

By using the quantity calculation above, and the maximum fill of each cylinder above, you can work out how many cylinders are typically required for your protected area.

Environmental Considerations.

Extinguishant IG‑541 is an inert gas and has zero GWP and zero ODP.

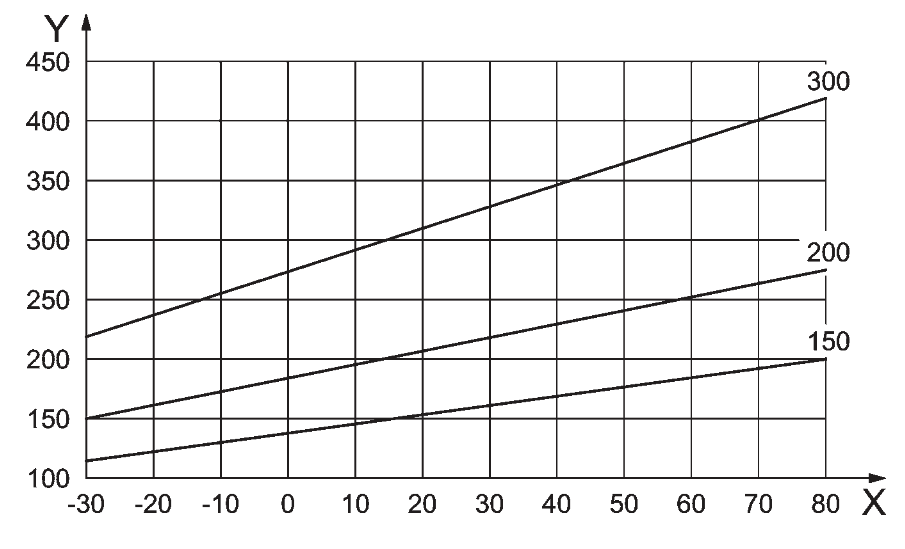

Temperature Vs Pressure Graphics

Temperature graphs are useful for verifying the pressure or your cylinders and whether they need replacing in line with the recommendations of BS EN 15004 which advises:

- Non-liquefied gases: for inert gas agents, pressure is an indication of agent quantity. If a container shows a loss of agent quantity or a loss of pressure (adjusted for temperature) of more than 5 %, it shall be refilled or replaced.

Pressure vs. temperature for IG-541 pressurised to 150, 200 and 300 bar at 15 °C

FAQs.

-

Can people be exposed to IG-541 or Inergen?

Yes, part of the approval process includes testing for adverse effects in humans at recommended design concentrations. Each of today's clean agents is safe for humans. While we recommend always exiting the hazard in the event of a fire, it is important that people not be harmed by the extinguishing system. Some manufacturers even offer live discharge testing in occupied rooms for demonstration purposes.

-

How does IG-541 or Inergen work?

Systems working on a total flooding principle apply an extinguishing agent to a three-dimensional enclosed space to achieve a concentration of the agent (volume percent of the agent in air) adequate to extinguish the fire. These types of systems may be operated automatically by detection and related controls or manually by the operation of a system actuator

-

What is the cost per cubic metre for an IG-541 or Inergen system?

It's a common misconception that the cost is per metre cubed, but the cost for a fire suppression system is based on volume, in addition to many other factors. There is not an equitable cost per cubic metre that can be universally applied to a suppression system application. Contact use for an accurate cost at hello@mepfire.com

-

IG-55 or IG-541?

Both clean agents have advantages over one another. IG-541 has the additional benefit of decreasing cardiac distress in the event of a discharge and usually requires slightly less cylinders however IG-55 is more widely available and easier to fill making it slightly cheaper.

View Our Full Site

Visit the full MEP Fire website for all your fire suppression needs.

All Rights Reserved | MEP Fire

We use cookies to ensure that we give you the best experience on our website.